ABOUT

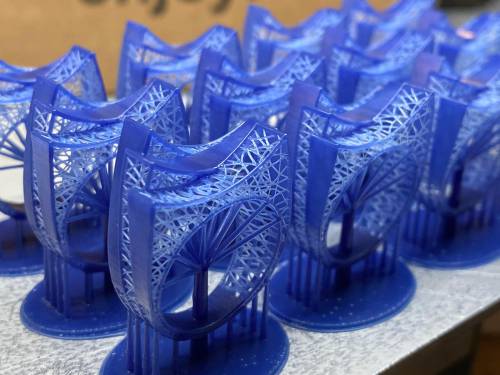

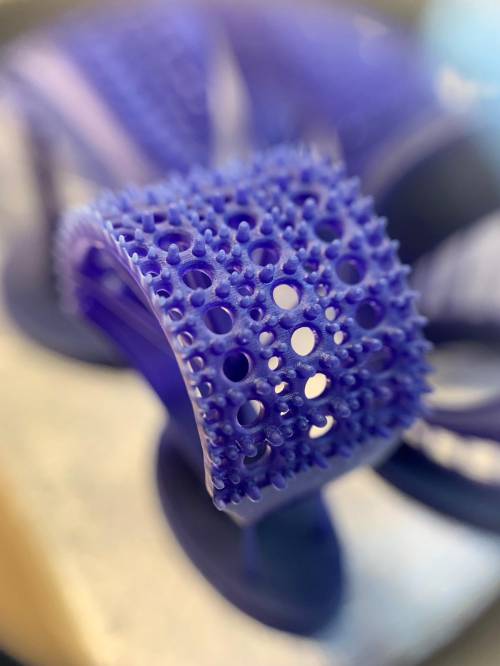

Cr3a is the entry-level castable resin by BlueCast. It is easily printable with all LCD and DLP 3d printers and ensures consistent and excellent casting results. UV post-curing is mandatory but differently from other competitor monomer-based resins that require complex and tricky treatments, our BC Cr3a just requires to be washed after printing and cured under UV light. For washing, you can use any alcohol or the X-cleaner liquid we supply. No hot water wash is required, no boiling, no overnight curing is needed to ensure the resin castability. For its properties, this castable resin is also frequently used by dental technicians for disilicate casting.

HOW TO USE IT

BLUECAST CR3A

DOWNLOAD

BEFORE PRINT

- Before using the resin, shake the resin bottle for 60 seconds. If the resin has been sitting in the tank, use a silicone spatula to ensure it is thoroughly mixed.

- Check the Z offset and perform calibration if necessary.

- It is recommended to filter the resin after each print cycle and store it in its original container to preserve its quality and prevent any changes in its characteristics.

- It is suggested to pre-scale the model by +1% to compensate for resin shrinkage.

POST-PRINTING CLEANUP

- Remove the prints from the build plate.

- Wash the prints in 90% to 99% ethyl alcohol.

- Dry the patterns using compressed air for optimal results.

- Place the prints in a vessel or plastic cup and fill it with CREA CURING LIQUID, ensuring that the patterns are fully submerged.

- Put the vessel with the patterns inside a UV oven and let it cure for 30 to 40 minutes, considering the lamp power and pattern size.

- The UV curing process is complete when the pattern color becomes lighter.

- Rinse the prints with distilled water and dry them using compressed air before proceeding to casting.