Choosing the Right Castable Resin: A BlueCast Selection Guide

BlueCast: Choosing the Right Castable Resin for Your Work (The Definitive Guide).

Are you struggling to decide which castable resin is best suited for your specific application? In this article, we will highlight and analyze the key differences between the latest high-performance resins from BlueCast: X-Wax, X-Wax Filigree, X-One v2, X-Nova, Cr3a, and BlueDental Cast.

We will evaluate crucial factors such as: Printability, Castability (by investment service), Post-processing, Physical Characteristics, and Suggested Applications.

|

Resin |

Printability (1-5) |

Castability (1-5) |

Post Processing |

Suggested Application |

Tensile Strength (UTS) |

TGA (%) |

|

X-Wax |

5 |

5+ |

Alcohol washing (IPA) |

Traditional and standard designs; Solid parts and men's rings; Stone Presetting |

9 MPa |

0.005 |

|

X-Wax Filigree |

5+ |

4 |

UV Post-curing |

Filigree and Middle Eastern Designs (Ultra-thin details) |

13 MPa |

0.015 |

|

X-One v2 |

5 |

5 |

Alcohol washing (IPA) |

Traditional and standard jewelry; Non-extreme filigree; Mass Production |

11 MPa |

0.010 |

|

X-Nova |

4 |

4 |

UV Post-curing |

Traditional, standard designs, and easy filigree; High Elastic Modulus for Stone Presetting |

13 MPa |

0.015 |

|

Cr3a |

4 |

3 |

UV Post-curing |

Standard designs and dental applications (Silver, Brass, Bronze) |

14 MPa |

0.020 |

|

BlueDental Cast |

5+ |

3 |

UV Post-curing |

Dental applications (Bridges, Crowns, Frameworks); High Dimensional Stability |

14 MPa |

0.020 |

Product Deep Dive

X-WAX

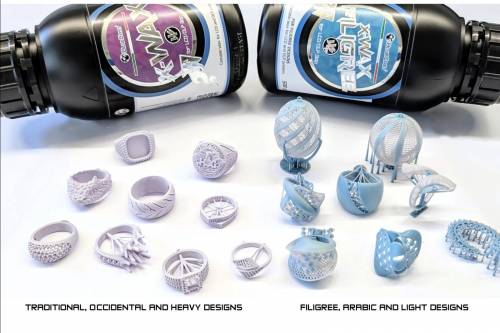

X-WAX is the world’s first resin to contain up to 80% real investment casting wax in its formulation. This formula is derived from its predecessor, X-One v2, where the technical polymer wall that simulated wax behavior has been replaced with traditional wax. The 80% represents the maximum possible saturation (meaning it is not technically possible for anyone to create a product with a higher percentage).

Suggested applications for X-Wax include traditional jewelry, stone-set and diamond rings, commemorative rings, and religious art. Due to its extremely high wax content, it can be challenging to print models with extended surfaces thinner than 0.5 mm, not because it’s technically impossible, but because the printed parts are soft, flexible, and have mechanical properties similar to wax models. However, it is possible to successfully print and handle details as thin as 0.3 mm, such as prong tips or bas-reliefs.

The mechanical resistance is, however, higher than that of wax jet printers (or "ptinters," likely a typo for "printers"), and for this reason, having an equivalent meltability, many printing services are changing their printing technology.

Thanks to its ability to function with low-temperature burnout cycles (below 640° Celsius), it is also particularly recommended for stone presetting before casting. For the use of real wax, this castable resin is slightly more fragile than X-One V2, but it is currently the most castable product on the market, boasting the lowest TGA in the absolute (0.005%).

X-Wax is compatible with ultra-fast 1 to2-hour casting burnout cycles.

X-WAX FILIGREE

Like Standard X-Wax, this castable resin also includes real casting wax in its formulation, but in a lower quantity. Its purpose is to allow the printing of very thin details typical of Turkish and Middle Eastern designs, even below 0.3 mm}. It is currently the best resin for filigree, highly appreciated even by users of the previous X-Filigree.

Naturally, as the wax content is lower than X-Wax, the two castability levels are not comparable. However, since it is intended for printing ultra-light models, it guarantees impeccable and residue-free casting for this type of design. Unlike X-Wax, UV post-curing is necessary after washing, both to increase rigidity and to prevent undesirable reactions with the investment material. Ultra-fast burnout is also possible for this resin, but at a higher temperature than X-Wax (740° VS 700° celsius).

X-One V2

X-One V2 has established itself over the last 3 years (from 2022 to 2025) as the easiest jewelry resin to cast. Its production will not be discontinued because, with a TGA of 0.010, it still represents one of the best products on the market, even if it has been surpassed in terms of pure castability by the new X-Wax.

Compared to X-Wax, since it is based on a waxy polymer and not real wax, it is easier to print and handle. This factor is often highly valued for those involved in mass production. Like all BlueCast resins, it is free of carcinogenic monomers, does not require post-curing, and consistently guarantees excellent casting results. Recommended applications include classic jewelry and printing of non-extreme filigree.

The famous claim "one resin - a thousand applications" clearly illustrates its fields of use.

X-Nova

X-Nova is a universal resin that allows the printing of most models, including some filigree. It is the BlueCast resin with the highest elastic modulus before the necessary UV cure. For this reason, it is often used for the pre-setting of synthetic stones and some natural ones.

Compared to X-Wax / X-Wax Filigree and X-One V2, it has a shrinkage that can reach up to 3% and must be controlled during the preparation of the printing profiles. For clean casting, a long UV cure is necessary, which can vary from 30 minutes to 2 hours depending on the lamp used. Once the post-curing process is complete, the resin’s color must change from bright green to pale green.

It is compatible with Novafab printers using the "Dark LT" printing profile.

Cr3a

For years, Cr3a has been the entry-level product in the BlueCast family, with a cost 25% lower than the flagship products. It is compatible with all DLP and LCD printers (including monochromatic, unlike the other 5 resins in this article for which monochromatic screens are recommended). It offers excellent definition and decent rigidity.

These characteristics have made it particularly appreciated by dental technicians, with the use of phosphate-bonded investments, for the printing of bridges, crowns, and frameworks. It is also an ideal product for mass production of silver, brass, and bronze artifacts and precious objects where minor casting defects can be tolerated. In this case too, a long UV cure is necessary, which can vary from 30 minutes to 2 hours depending on the lamp used.

BlueDental Cast

This resin was developed to be used primarily in dental applications where accuracy, dimensional stability, and lack of shrinkage are essential requirements. The pastel pink color was chosen to allow excellent visibility of details and finishing. The materials used make it perfect for ultra-fast casting with free-expanding phosphate-bonded investments.